The Manufacturing Unit

The manufacturing process

Self-confidence is the precursor to pride, and we want Iran to be proud. Therefore, in the coming years, we want to become a reference company for heavy metal megastructures, especially for the construction of power plants, refineries, petrochemical plants, mines, industrial plants, high-rise buildings, towers, bridges, tanks, etc. at the national and international levels. What lies ahead is a difficult road with many obstacles to overcome with will, diligence, and innovation. In the production of metal parts, the choice of the manufacturing process is very important. Most of the manufacturing processes are automated. We do the work in 14 steps, from signing the contract to the project handover, as follows.

1- Participation in the tender, agreement, and signing of the contract

In the organizational structure of Sazvar Sazeh Azarestan, a department called Business Development has been established, which is responsible for monitoring all tenders in the market. Business Development Department consists of two units, Digital Marketing and Tender Expert, and each unit performs its tasks based on the guidelines explained by the managers. In the Tender Expert unit, the drawings are fully modeled and the list of required materials such as steel, nuts and bolts, paint, etc. are extracted and detailed pricing is done. The evaluation documents as well as the engineering and technical documents are reviewed by the Business Development Department and the final results are summarized in the form of a price proposal.

2- Preparation of manufacturing drawing and obtaining approval

Preparation of the manufacturing drawing is a crucial step in the product manufacturing process, which begins with the review of the structural single-line diagrams. These diagrams are converted into manufacturing drawings using specialized software such as TEKLA, BOCAD, AUTOCAD (manufacturing drawing creation), SAP, and ETBAS (structural design). These drawings are submitted to the employer for final approval. After the final approval of the manufacturing drawing, these documents are forwarded to the Manufacturing Engineering Department to calculate the raw materials.

3- Project Planning and Manufacturing Engineering

After receiving the approved drawing from the employer and preparing the manufacturing drawing in the Engineering Department, estimation and procurement of raw materials are carried out in parallel. Factors such as material characteristics and properties, shape, size, and thickness of the part, dimensional tolerances and required surface smoothness, functional requirements of the part, manufacturing volume (quantity), level of automation required to meet the manufacturing volume and pace, unit cost and a combination of aspects of manufacturing operations are considered mandatory in the Manufacturing Engineering Department. In this department, special attention is paid to optimal consumption and maximum reduction of material waste. One of the most fundamental departments in any factory is undoubtedly the Project Planning and Control (PPC), which is carefully carried out in Sazvar Sazeh Azarestan Company with both project and manufacturing perspectives to meet the needs of employers and improve the level of employer service. In the Manufacturing Planning Department, at the two levels of capacity measurement (tactical) and manufacturing planning (operational), when reviewing the capacities for parts preparation, manufacturing, and coating, all necessary activities are carried out based on the priority of parts assembly and following the project plan and resource management. Project Control Integrated System software has been developed by professional programmers exclusively for Sazvar Sazeh Azarestan company. In this software, all project information from the beginning of the contract to the end of the installation is recorded by the units in different modules. It also records the daily, weekly, monthly, and annual capacity of the production lines and allocates the work according to the available capacity of each line.

4- Quality control of raw materials before delivery to production lines

At Sazvar Sazeh Azarestan Company, no product is manufactured without performing various quality control checks on the raw materials. The quality control specialists perform destructive and non-destructive tests to measure the quality of raw materials before they are delivered to the production lines. Quality control experts start quality control based on recognized technical criteria following international standards and use advanced instruments before the raw materials enter the production lines and follow them up to the final stage, i.e. delivery of the product.

5- Cutting, preparation of parts, drilling, flanging

In the fifth step, we forward the manufacturing drawings approved by the employer to the supervisors of manufacturing, planning, project control, and quality control. According to the instructions and after coordination with the supervisors, we send the procured steels to the Cutting and Parts Preparation unit after quality control. At Sazvar Sazeh Azarestan we cut stiffeners and supplementary parts with modern machines, including fully automatic CNC cutting machines, CNC hot and cold cutting machines, CNC plasma, and guillotine cutting machines. In this unit, two methods of punching and drilling are used, for which the factory is equipped with CNC punching and drilling machines.

6- Edge preparation: a prerequisite for initial assembly

In the strip forming and sheet metal working step, the strips are placed side by side and the beveling process is performed on them. In the beveling process, the desired edges must be processed before the initial assembly of the product, so that the initial welding can be performed without any problems. Beveling plays an important role in the quality of the joints of the parts. After performing the above steps and quality control of the manufactured parts, the initial assembly of the product begins.

7- Mechanical and machine assembly

After cutting and preparation of the parts, the initial assembly process of the parts begins with H-forming machines. The manufacturing of metal parts using mechanical and machine methods are two basic components of the initial assembly process. When manufacturing metal parts, it is best to assemble multiple parts using fasteners or techniques such as welding.

To avoid significant assembly costs, it may also be more cost effective to manufacture the metal part in one piece without welding.

8- Initial welding and straightening of the product

After the initial assembly of the parts, this step of the manufacturing process is about joining the parts together. In fact, the initial welding of the parts is an assembly process. One of the advantages of initial welding is the possibility of producing very complex parts. The strength of the pre-welded parts facilitates the manufacturing process and allows the next steps to be carried out. After the initial welding, deformations may occur due to the heat effect on the parts. Thus, the parts are passed through the straightening machine and the tolerance of the standards is achieved. At this step, the parts are certified and provided with a nameplate.

9- Final welding and assembly

Quantity and pace of manufacturing are very important in determining the manufacturing processes of parts in the factory as a manufacturing management system. In the final assembly and welding phase, the parts that complete the elements are connected to the main body and in this step, the structural elements are completed. Most of the welding operations in this step are manual and require very high precision and adherence to welding procedures. Since this is the last step of part production, strict quality control of the produced parts is required. In this context, various non-destructive tests (NDT) are performed on the produced parts.

10- Cleaning and product delivery

In this part, the appropriate tools and machines such as angle grinders, slag removers, cutting blades to remove weld spatter, etc. are used. After cleaning the parts, final dimensional checks and non-destructive tests are performed on all parts of parts. After approval by the quality control team, the parts are delivered to the supervisors’ representatives and the employer’s inspectors. After the parts are approved and delivered, the product is loaded onto special trucks and left the production halls.

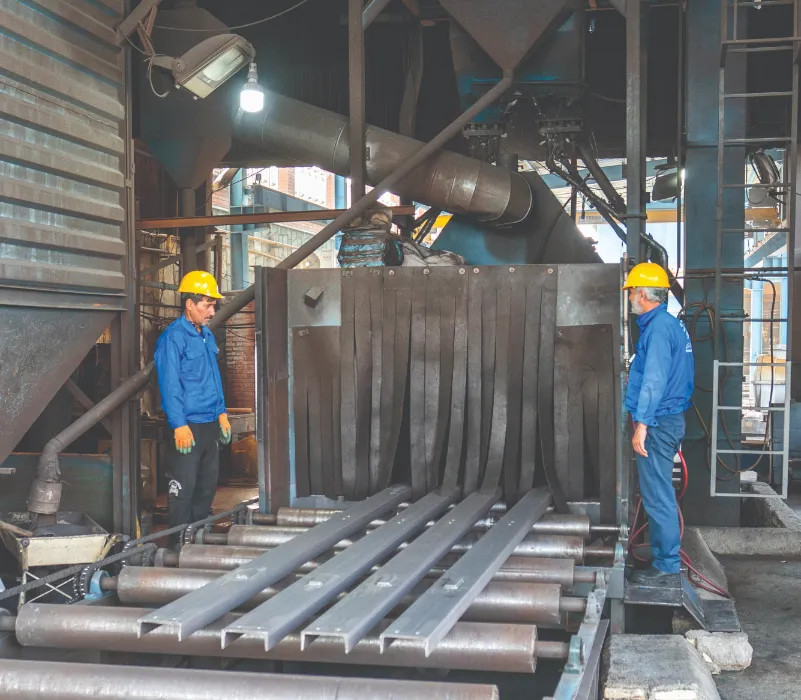

11- Preparation of surfaces before painting

Sandblasting and shot blasting are two different methods of sanding, decontaminating, removing stains, and polishing surfaces. In sandblasting, the surface is abraded with sand particles, while in shot blasting, the same process is performed with metal balls that are forced through a centrifugal system with pressure on the surface of the part. This method is one of the most common and ideal surface cleaning methods, where a high-pressure jet of abrasive materials is directed at the desired surface. This clears the surface of dust, oil, stains, and dirt. In the surface preparation department of Sazvar Sazeh Azarestan company, it is possible to achieve all degrees of surface roughness according to international standards.

12- The result of the production after finishing the painting

Since the result of manufacturing can be seen objectively after this step is completed, it is considered one of the most important steps. The humidity and temperature in the environment of the painting room are measured with a thermometer and a hygrometer during the painting process. After painting, the structures are checked for the desired thickness, the accuracy of paint adhesion, and finally the flatness of the paint surface according to international standards. A coating thickness gauge is used to determine the dry film thickness (DFT) of the paint, and the cross-cut and X-cut methods are used for paint adhesion accuracy. Airless machines are also used for painting.

13- Packing; protection of manufactured parts

Packing and arrangements for long-term storage are made to avoid damage to parts due to transport vibrations and possible impacts and to keep surfaces clean until installation. For this purpose, Sazvar Sazeh Azarestan Company packs all its products in a special way. The main points of packing include holding resistant elements, placing temporary wooden bases, covering shock-prone parts, wrapping them with nylon, and placing warning labels and a packing list. To avoid damage to surfaces during packing, timber and wood with foam wrapping are used. In addition, to avoid damage to the edges of the product, resistant rubber blocks are placed between the parts. At this step, a touch-up is also carried out at the same time.

14- Product shipping, the last step in the manufacturing process

Product shipping is the last step in the manufacturing process. In this step, based on the designations of the parts and the priorities announced by the installation unit, the packing lists are prepared, and, depending on the dimensions and tonnage of the parts, suitable trailers are selected to transport the cargo as best as possible. After the loading is completed, the strength of the parts is checked and the final steps of quality control of the manufactured products are carried out, the trailer is driven to the 80-ton digital scale in the factory and the cargo is weighed. The scale at the Sazvar Sazeh Azarestan factory is calibrated every 3 months.