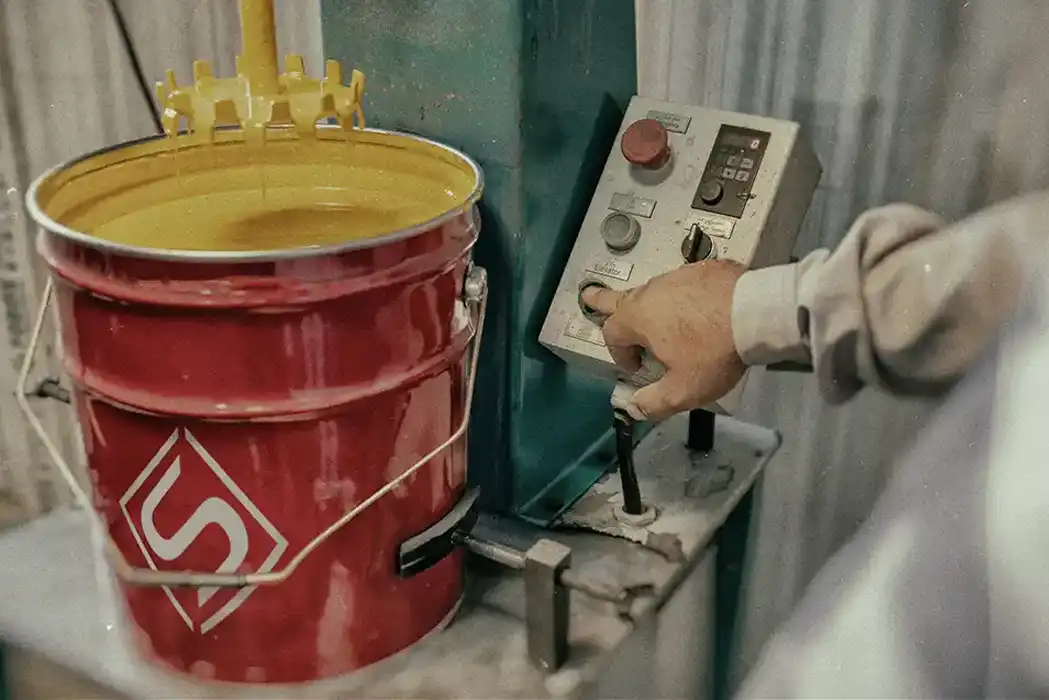

Preparation of surfaces before painting

Sandblasting and shot blasting are two different methods of sanding, decontaminating, removing stains, and polishing surfaces. In sandblasting, the surface is abraded with sand particles, while in shot blasting, the same process is performed with metal balls that are forced through a centrifugal system with pressure on the surface of the part. This method is one of the most common and ideal surface cleaning methods, where a high-pressure jet of abrasive materials is directed at the desired surface. This clears the surface of dust, oil, stains, and dirt. In the surface preparation department of Sazvar Sazeh Azarestan company, it is possible to achieve all degrees of surface roughness according to international standards.